Types of Laser Metal Cutting Machines and Their Unique Features

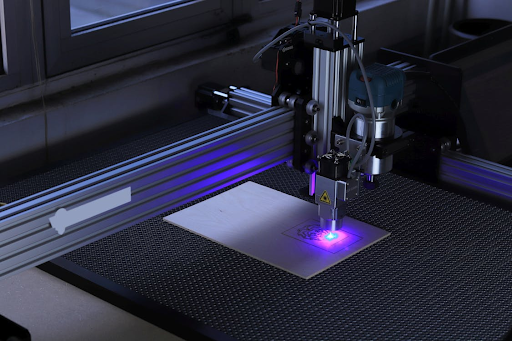

In the realm of industrial manufacturing, precision and efficiency are paramount. This is where laser metal cutting machines come into play, revolutionizing the way metal components are fabricated.

These machines utilize the power of lasers to cut through various types of metals with unparalleled accuracy and speed. However, not all laser metal cutting machines are created equal. They come in different types, each offering unique features tailored to specific needs and applications.

In this article, we will explore the various types of laser metal cutting machines and delve into their distinctive features.

1. Fiber Laser Cutting Machines

Fiber laser cutting machines have gained widespread popularity in recent years due to their exceptional cutting capabilities and efficiency. These machines employ fiber lasers, which generate a concentrated beam of light that is transmitted through a fiber optic cable to the cutting head.

The intense energy of the laser beam melts and evaporates the metal, creating precise cuts with minimal heat-affected zones.

Unique Features:

- High Speed and Precision: Fiber laser cutting machines are renowned for their fast cutting speeds and high levels of precision, making them ideal for cutting intricate patterns and complex shapes.

- Low Maintenance: Compared to other types of laser cutting machines, fiber lasers require minimal maintenance, resulting in reduced downtime and increased productivity.

- Versatility: Fiber laser cutting machines can effortlessly cut through a wide range of metals, including stainless steel, aluminum, copper, and brass, making them suitable for diverse industrial applications.

- Energy Efficiency: Fiber lasers are highly energy-efficient, consuming less power compared to other laser technologies, which translates to lower operating costs.

2. CO2 Laser Cutting Machines

CO2 laser cutting machines utilize carbon dioxide gas as the laser medium to generate the cutting beam. These machines have been a staple in the manufacturing industry for several decades, offering reliable performance and versatility.

Unique Features:

- Versatile Cutting Abilities: CO2 laser cutting machines are capable of cutting through a variety of materials, including metals, plastics, wood, and ceramics, making them suitable for a wide range of applications.

- Smooth Edge Quality: The CO2 laser beam produces smooth and clean-cut edges, minimizing the need for secondary finishing processes.

- Cost-Effectiveness: While initial investment costs may be higher compared to other types of laser cutting machines, CO2 lasers offer cost-effective operation over the long term, especially for applications requiring thick metal cutting.

- Ease of Maintenance: CO2 laser cutting machines are relatively easy to maintain, with fewer components susceptible to wear and tear.

3. YAG Laser Cutting Machines

YAG (Yttrium Aluminum Garnet) laser cutting machines utilize solid-state lasers, where the laser medium is a crystal doped with rare-earth elements such as neodymium. While not as commonly used as fiber or CO2 lasers, YAG lasers have specific advantages in certain applications.

Unique Features:

- Highly Reflective Material Cutting: YAG lasers excel at cutting highly reflective materials such as brass, copper, and gold, which can be challenging for other types of lasers.

- Greater Thickness Capability: YAG lasers are capable of cutting thicker materials compared to CO2 lasers, making them suitable for applications requiring deeper penetration.

- Stability and Reliability: YAG lasers offer excellent stability and reliability, ensuring consistent performance over prolonged periods.

4. Disk Laser Cutting Machines

Disk laser cutting machines utilize a solid-state laser technology similar to YAG lasers but with a different laser medium configuration. These machines offer distinct advantages, particularly in terms of energy efficiency and cutting speed.

Unique Features:

- High Power Efficiency: Disk lasers boast high power efficiency, resulting in reduced energy consumption and operating costs.

- High Cutting Speeds: With their innovative design, disk lasers can achieve higher cutting speeds compared to other types of lasers, increasing productivity and throughput.

- Reduced Maintenance Requirements: Disk laser cutting machines require minimal maintenance, thanks to their robust design and fewer moving parts.

Conclusion

Laser metal cutting machines have revolutionized the manufacturing industry, offering unparalleled precision, efficiency, and versatility. From fiber lasers to CO2 lasers, YAG lasers, and disk lasers, each type of laser cutting machine brings its own set of unique features and advantages.

By understanding the characteristics of each type, manufacturers can choose the most suitable option for their specific needs, ensuring optimal performance and productivity in metal fabrication processes. As technology continues to evolve, laser metal cutting machines will undoubtedly play a central role in shaping the future of industrial manufacturing.