Double Offset VS Triple Offset Butterfly Valve

Butterfly valves are key in many business applications. They can efficiently control the flow of liquids and gases. This is why they are so important. These valves are known for their small size. They also open and close quickly. They are cheaper than other valves. In the class of butterfly valves, we mainly consider double-offset and triple-offset valves. They have specialized designs that improve performance in many stressful situations. This article delves into the details of these two sorts of butterfly valves. It evaluates their designs, functions, benefits, and packages. These will help you pick the one that suits your needs best.

Understanding Butterfly Valves

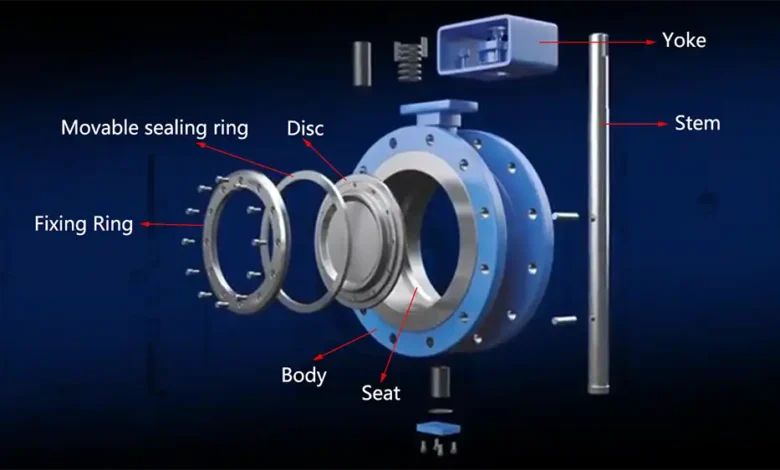

Basic Structure

A butterfly valve includes a circular disc or vane that rotates in the valve frame to open or near the flow course. The disc is set up on a shaft. The shaft passes through the valve body and is hooked to an actuator. The actuator controls the rotation of the disc. When the valve opens, the disc is parallel to the drift path. Fluid can skip with little resistance. The disc is perpendicular to the glide when closed, effectively blocking it.

Key Features

Butterfly valves have a very small size. This makes them ideal for programs where space is tight.

They are lighter than other valve types, such as gate or globe valves. This makes installation easier and reduces the need for structural guides.

Quick Operation: The rotation is from fully open to fully closed. It allows fast operation. This is important in some management packages.

Butterfly valves are cost-effective. They cost much less to make and maintain than other valve types.

Double Offset Butterfly Valve

Design and Working Principle

The double-offset butterfly valve, also called a high-performance butterfly valve, has offsets from the valve’s centerline. The first Offset is from the disc’s centerline to the pipe’s centerline. The second Offset is from the valve’s centerline to the seat’s centerline. These offsets make the disc move away from the seat quickly when starting, reducing friction and wear.

Advantages

The double offset layout minimizes contact between the disc and the seat, reducing friction and increasing the valve’s carrier life.

They can shut very tightly. This makes them good for applications where leakage is not allowed.

Double-offset butterfly valves can handle more stress than concentric ones. Their higher pressure ratings make them suitable for extra-demanding packages.

Applications

Double offset butterfly valves are usually utilized in industries including:

Oil and Gas: For throttling and shut-off applications in pipelines and processing facilities.

Chemical Processing: This handles aggressive chemical compounds and ensures leak-tight performance.

Power Generation: Steam management and other excessive-strain programs in cooling structures.

Triple Offset Butterfly Valve

Design and Working Principle

The triple offset butterfly valve, called the triple eccentric valve, adds a third offset to the layout. In addition to the 2 offsets in double offset valves, the 1/3 offset is an angle in the seat surface. This design is unique. It guarantees that the disc contacts the seat belt at the final closure, making it frictionless and durable.

Advantages

The triple offset design allows for a metal-to-metal seal. It guarantees zero leakage, even at high pressure and temperature.

High-Temperature and Pressure Capabilities: These valves can resist extreme temperatures and pressures. This makes them ideal for the toughest applications.

Applications

Triple offset butterfly valves are specifically perfect for:

Petrochemical: For managing superheated steam, hydrocarbons, and other challenging fluids.

Power Plants: In high-pressure steam strains and feedwater systems.

Marine and Offshore: For seawater cooling structures, ballast systems, and other marine programs.

Comparison: Double Offset vs. Triple Offset Butterfly Valve

Performance

Leakage is the issue. Double offset valves shut off well. But, triple offset valves have truly 0-leakage. This is due to their steel-to-metal seal.

Triple offset valves are more durable. They last longer because their layout removes the disc and seat friction.

Triple-offset valves can handle higher pressures and temperatures. They are better than double-offset valves for tougher situations.

Cost

Initial Cost: Double-offset valves are often much cheaper than triple-offset valves. This is due to their simpler design and production methods.

Maintenance: Triple offset valves are initially extra expensive. However, they have often had lower upkeep prices over the years. This is because of their improved durability and longer lifespan.

Application Suitability

Double Offset is best for programs requiring reliable shut-off. Such programs are in the oil and fuel or chemical industries, and they are for moderate strain and temperature.

Triple Offset valves are ideal for intense situations. They involve 0 leakage, excessive strain, and high temperature. These are critical in petrochemical, power generation, and marine industries.

Choosing the Right Valve

When finding out between a double offset and a triple offset butterfly valve, numerous factors need to be considered:

Application Requirements: Assess the precise necessities of your software, along with pressure, temperature, and the nature of the fluid being managed.

Cost vs. Benefit: Consider the preliminary cost towards the long-term blessings of decreased maintenance and extended carrier existence.

Leakage Tolerance: Determine the appropriate stage of leakage in your application. A triple offset valve is preferred for 0-leakage requirements.

Durability Needs: Evaluate the valve’s anticipated lifespan and protection wishes based on the running situations.

For industries where extreme conditions and zero leakage are paramount, consisting of petrochemical and electricity generation, the triple offset butterfly choose one

valve is often preferred. However, the double offset butterfly valve offers a valuable solution. It is powerful and dependable for programs with less worrying conditions.

Conclusion

Both double Offset and triple offset butterfly valves have their specific blessings. They are suitable for different uses. The double offset valve balances performance and cost. It is ideal for many commercial uses. Conversely, the triple offset valve excels in severe conditions, providing extraordinary durability and zero leakage overall performance.

Understanding your application’s specific wishes is critical to making an informed decision. You may need a valve that can handle high strain and heat. Or, one that shuts off reliably with little upkeep. The key is to pick one that fits your needs and budget.